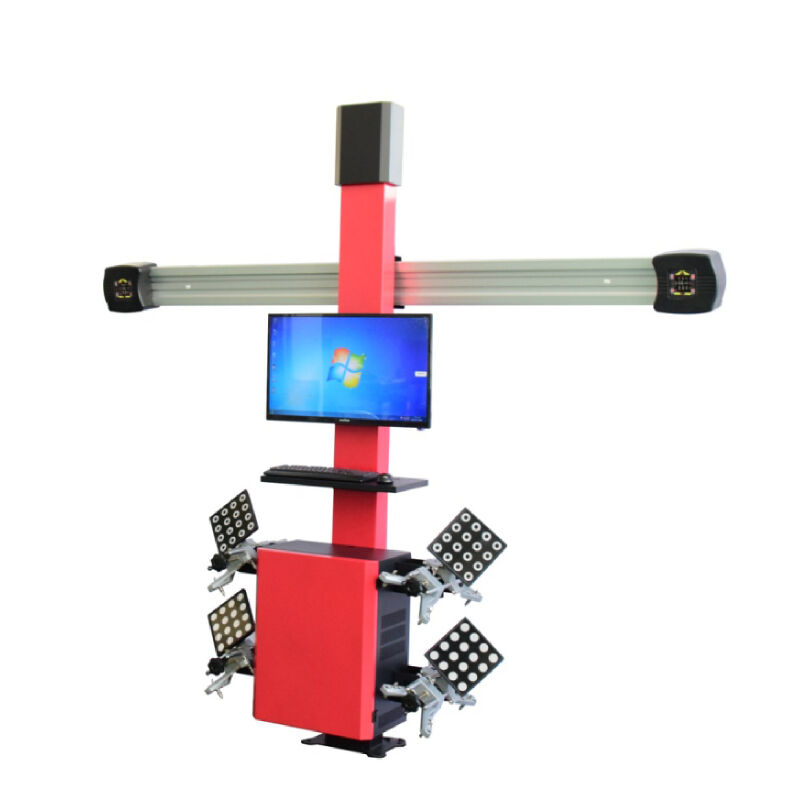

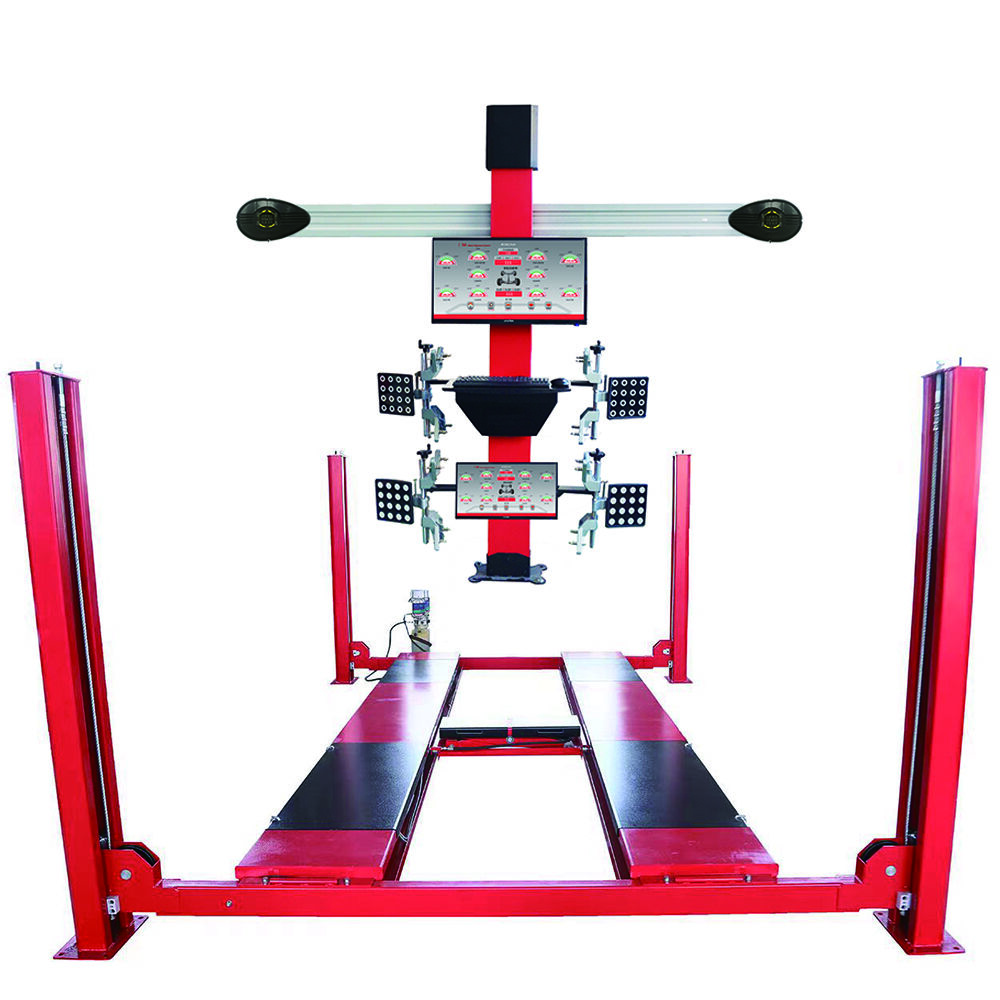

safe wheel alignment in stock

Safe wheel alignment in stock represents a revolutionary approach to automotive maintenance, combining precision engineering with readily available service solutions. This advanced system ensures vehicles maintain optimal tire positioning and suspension geometry while providing immediate access to professional alignment services. The safe wheel alignment in stock technology incorporates cutting-edge laser measurement systems, computerized diagnostic tools, and precision adjustment mechanisms that deliver accurate results consistently. Modern alignment equipment features three-dimensional measuring capabilities, allowing technicians to assess camber, caster, and toe angles with exceptional accuracy. The system utilizes advanced sensors and software algorithms to detect even minute deviations from manufacturer specifications, ensuring comprehensive alignment correction. Safety remains paramount in the design of safe wheel alignment in stock solutions, with multiple protective features including automatic shutoff systems, secure vehicle restraints, and operator safety protocols. The technology integrates seamlessly with existing service bay infrastructure, requiring minimal modifications while maximizing efficiency. Digital displays provide real-time feedback during alignment procedures, enabling technicians to make precise adjustments while monitoring progress continuously. The system accommodates various vehicle types, from compact cars to light trucks, with adjustable platforms and universal mounting systems. Quality control measures include automated calibration routines and verification protocols that maintain equipment accuracy over extended periods. Environmental considerations drive the development of energy-efficient components and reduced waste generation throughout the alignment process. The safe wheel alignment in stock solution addresses critical automotive maintenance needs while prioritizing operator safety, equipment reliability, and service quality, making it an essential investment for professional service facilities seeking to enhance their capabilities and customer satisfaction levels.