In the rapidly evolving automotive service industry of 2025, mechanics are increasingly choosing advanced equipment that maximizes efficiency while ensuring safety. The 4 post car lift has emerged as the preferred choice for professional workshops, offering unparalleled stability and versatility for vehicle maintenance operations. Modern automotive service facilities demand reliable lifting solutions that can handle diverse vehicle types while providing mechanics with comfortable working conditions and optimal accessibility to vehicle components.

Superior Stability and Safety Features

Enhanced Structural Design

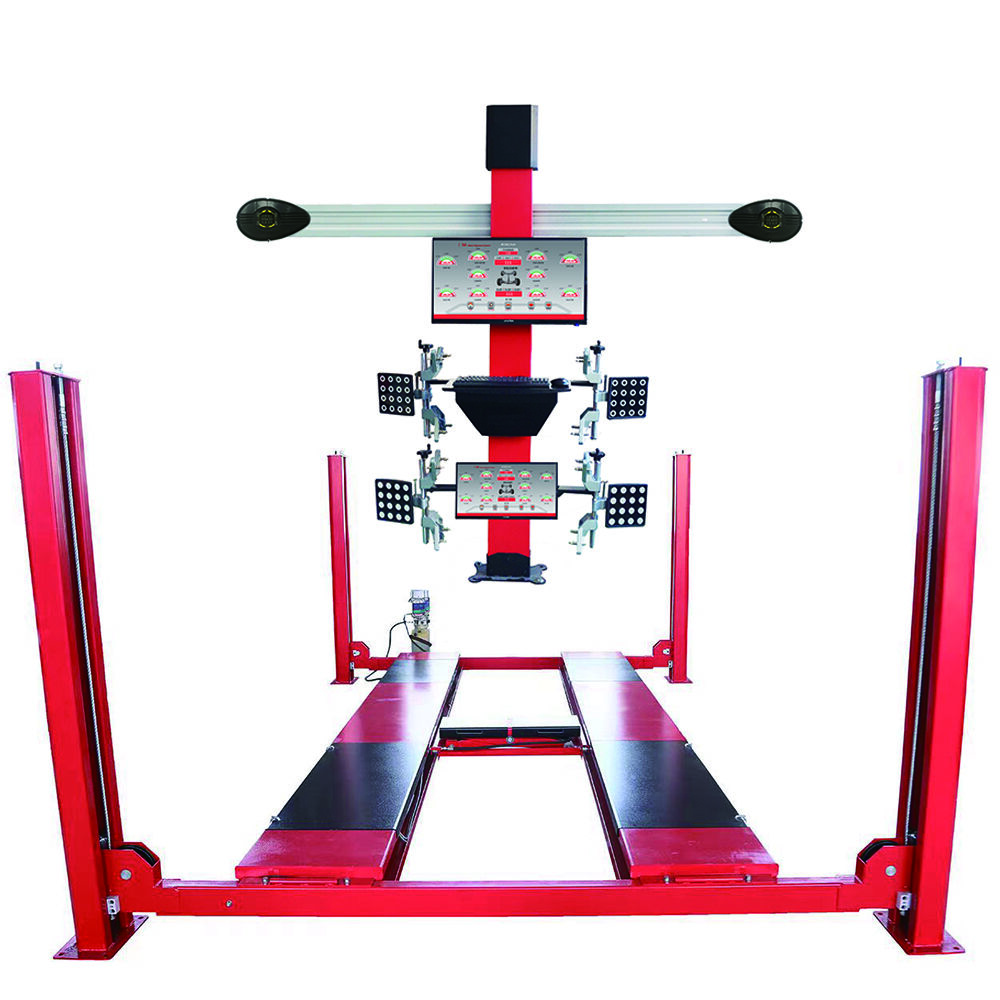

The structural integrity of a 4 post car lift provides mechanics with confidence during every service operation. Unlike traditional two-post systems, this configuration distributes vehicle weight across four support points, creating a stable platform that eliminates concerns about vehicle movement during maintenance. The robust frame construction incorporates reinforced steel components that can withstand heavy-duty commercial use while maintaining precise alignment specifications.

Advanced safety mechanisms integrated into modern 4 post car lift designs include automatic locking systems that engage at multiple height positions. These fail-safe features prevent accidental lowering during maintenance procedures, protecting both vehicles and technicians from potential accidents. The symmetrical weight distribution characteristic of four-post systems significantly reduces the risk of vehicle tipping or shifting during lifting operations.

Operator Safety Protocols

Professional mechanics appreciate the comprehensive safety protocols built into contemporary 4 post car lift systems. Emergency stop buttons strategically positioned around the lift perimeter provide immediate shutdown capability in critical situations. Audible warning signals alert workshop personnel when lifting or lowering operations commence, ensuring workspace awareness and preventing accidents.

The open-bay design of four-post lifts allows mechanics to maintain visual contact with the vehicle throughout the entire lifting process. This transparency enables real-time monitoring of load positioning and immediate identification of any irregularities that might compromise safety. Hydraulic systems incorporate pressure relief valves and backup support mechanisms that activate automatically if primary systems experience failures.

Versatility in Vehicle Applications

Multi-Vehicle Compatibility

The adaptability of a 4 post car lift makes it indispensable for modern service facilities that handle diverse vehicle portfolios. From compact passenger cars to large SUVs and light commercial trucks, these lifts accommodate varying wheelbases and weight distributions with ease. Adjustable runway extensions and customizable support configurations enable mechanics to service vehicles with different specifications using the same equipment.

Specialty automotive shops particularly benefit from the flexible positioning capabilities offered by four-post lift systems. Classic car restoration projects require stable, long-term storage solutions that prevent frame distortion while allowing comprehensive access for detailed work. The gentle lifting action and even weight distribution protect vintage vehicle frames from stress concentrations that could cause structural damage.

Service Operation Efficiency

Mechanics working with 4 post car lift systems report significant improvements in service efficiency compared to alternative lifting methods. The drive-on capability eliminates time-consuming positioning procedures required with other lift types, allowing vehicles to be elevated quickly and safely. This efficiency translates directly into increased daily service capacity and improved customer satisfaction through faster turnaround times.

The unrestricted access provided by four-post configurations enables simultaneous multi-technician operations on single vehicles. While one mechanic performs undercarriage inspections, another can simultaneously work on wheel assemblies or suspension components. This parallel processing capability maximizes labor utilization and reduces overall service completion times.

Economic Advantages for Workshop Operations

Cost-Effectiveness Analysis

Investment in a 4 post car lift delivers measurable returns through increased operational capacity and reduced labor costs. The enhanced productivity achieved through faster vehicle positioning and improved access translates into higher daily service volumes without proportional increases in staffing requirements. Workshop owners report typical payback periods of 18-24 months based on increased throughput capabilities.

Maintenance costs associated with four-post lift systems remain minimal due to their simple mechanical design and robust construction. The reduced complexity compared to alternative lift types results in fewer failure points and extended service intervals between maintenance procedures. Quality 4 post car lift installations often provide decades of reliable service with proper care and periodic inspections.

Space Utilization Benefits

Modern workshop layouts benefit significantly from the space-efficient design characteristics of 4 post car lift installations. The compact footprint relative to lifting capacity allows optimal bay configuration while maintaining adequate clearances for equipment access and personnel movement. Overhead clearance requirements remain reasonable, enabling installation in facilities with standard ceiling heights.

The ability to stack vehicles using four-post lifts provides additional storage capacity in space-constrained facilities. This vertical storage capability proves particularly valuable for shops handling multiple vehicles simultaneously or requiring extended storage for restoration projects. The stable platform created by these lifts ensures vehicles remain secure during extended elevation periods.

Advanced Technology Integration

Hydraulic System Innovations

Contemporary 4 post car lift systems incorporate advanced hydraulic technologies that enhance performance while reducing energy consumption. Variable-speed pumps automatically adjust flow rates based on load requirements, optimizing lifting speeds while minimizing power consumption. Integrated filtration systems maintain hydraulic fluid cleanliness, extending component life and ensuring consistent performance.

Smart control systems monitor hydraulic pressure continuously, providing real-time diagnostics and predictive maintenance alerts. These intelligent features prevent unexpected failures while optimizing operational efficiency through automated system adjustments. Remote monitoring capabilities enable service providers to track equipment performance and schedule maintenance proactively.

Digital Control Features

Modern 4 post car lift installations feature intuitive digital control interfaces that simplify operation while providing comprehensive system monitoring. Touchscreen displays present clear operational status information and guide operators through proper lifting procedures. Programmable height presets enable quick positioning for common service operations, further enhancing productivity.

Integrated data logging capabilities track usage patterns and maintenance requirements, providing valuable insights for workshop management. These analytics help optimize service scheduling and equipment utilization while ensuring compliance with safety inspection requirements. Network connectivity options enable integration with workshop management systems for seamless operational coordination.

Future-Proofing Workshop Investments

Evolving Automotive Technology

The automotive industry's transition toward electric vehicles and advanced powertrains creates new service requirements that 4 post car lift systems accommodate effectively. Electric vehicle batteries require specialized handling procedures that benefit from the stable platform and unrestricted access provided by four-post configurations. The ability to support vehicles for extended periods enables comprehensive battery system diagnostics and repairs.

Autonomous vehicle maintenance protocols demand precise positioning and stable support during calibration procedures. The consistent platform alignment achieved with four-post lifts ensures sensor systems maintain proper orientation during service operations. This precision becomes increasingly critical as vehicles incorporate more sophisticated automation technologies requiring exact positioning specifications.

Regulatory Compliance Considerations

Safety regulations governing automotive service facilities continue evolving, with increasing emphasis on equipment reliability and operator protection. The inherent safety characteristics of 4 post car lift systems align well with current regulatory trends while providing flexibility to accommodate future requirements. Compliance documentation and traceability features integrated into modern systems simplify inspection processes and regulatory reporting.

Environmental considerations increasingly influence equipment selection decisions, with energy efficiency becoming a key evaluation criterion. Four-post lift systems typically consume less energy than alternative configurations due to their efficient hydraulic designs and reduced cycle times. This efficiency advantage becomes more significant as utility costs increase and environmental regulations tighten.

FAQ

What weight capacity should I consider for a 4 post car lift

Weight capacity selection depends on your specific vehicle service requirements. Most professional installations utilize lifts rated between 8,000 and 12,000 pounds to accommodate standard passenger vehicles, light trucks, and SUVs. Heavy-duty applications may require 15,000-pound or higher capacity units. Consider your heaviest anticipated vehicle weight plus a safety margin of at least 20% when selecting capacity specifications.

How much space is required for 4 post car lift installation

Standard installations require approximately 12 feet by 24 feet of floor space, with additional clearance around the perimeter for safe operation. Ceiling height requirements typically range from 11 to 14 feet depending on desired lifting height and vehicle clearance needs. Professional installation assessment should evaluate your specific facility dimensions and operational requirements to determine optimal positioning and clearances.

What maintenance is required for reliable operation

Regular maintenance includes monthly visual inspections of hydraulic components, annual professional safety inspections, and periodic hydraulic fluid changes every 2-3 years. Daily operational checks should verify proper function of safety locks, control systems, and lifting mechanisms. Keeping detailed maintenance records ensures optimal performance and regulatory compliance while maximizing equipment lifespan.

Can a 4 post car lift accommodate different vehicle types

Modern four-post lifts feature adjustable runway systems that accommodate vehicles with wheelbases ranging from compact cars to extended cab trucks. Optional accessories like motorcycle adapters, ATV platforms, and alignment equipment expand versatility further. The stable four-point support system safely handles vehicles with varying weight distributions and configurations, making it ideal for multi-service facilities handling diverse vehicle portfolios.